Induction and synchronous motors are today indispensable elements in industry and the energy sector. They differ in their design, operating mechanism and applications, making them suitable for a variety of engineering tasks. Their use is particularly important in the power generation sector, where they act as generators.

Understanding the differences between induction and synchronous motors is critical when selecting the appropriate equipment to meet specific industrial needs. These differences include not only design and operating characteristics, but also energy efficiency, cost, serviceability and durability.

Induction motors are attractive for their versatility and reliability, making them suitable for numerous applications. In contrast, synchronous motors stand out for their high efficiency and precision, which is particularly important in situations where precise control over the parameters of the energy produced is required.

In this article we will scrutinise the technical and operational differences between these two types of motors, with a focus on their role in generators. This will provide a deeper understanding of the factors to consider when choosing between induction and synchronous motors for various industrial and power generation applications. Recognising their unique properties and advantages will help to identify the best solution for specific requirements, whether in renewable energy, heavy industry or power supply design.

Comparative analysis of induction and synchronous motors: key characteristics, advantages and disadvantages

| Characterisation | Asynchronous Motor | Synchronous motor |

| Design | Simple and reliable design, squirrel cage rotor (‘squirrel wheel’), no sliding contacts | Complex design with windings on the rotor requiring an external power supply |

| Principle of operation | Working with the speed difference between the rotating magnetic field and the rotor | The rotor rotates synchronously with the speed of the rotating magnetic field |

| Inrush current | High inrush current | Relatively low inrush current |

| Power regulation | Less efficient regulation, frequency converters are often used | High accuracy of power control |

| Generator applications | Used in wind turbines and small hydroelectric power plants | Widely used in large power plants |

| Preventing the flicker effect | They don’t prevent | Help prevent the flicker effect |

| Advantages | Low cost, easy maintenance, reliability | High efficiency and accuracy, stable operation |

| Disadvantages | Lower efficiency at partial loads, high inrush current | Higher cost, difficult to maintain |

Design Features

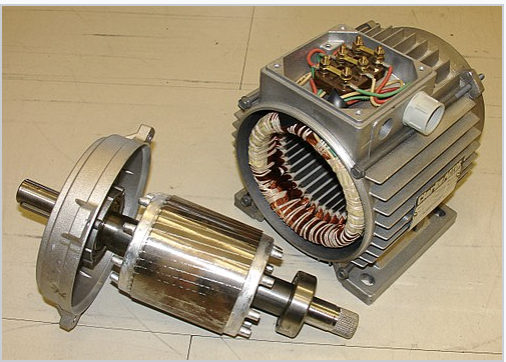

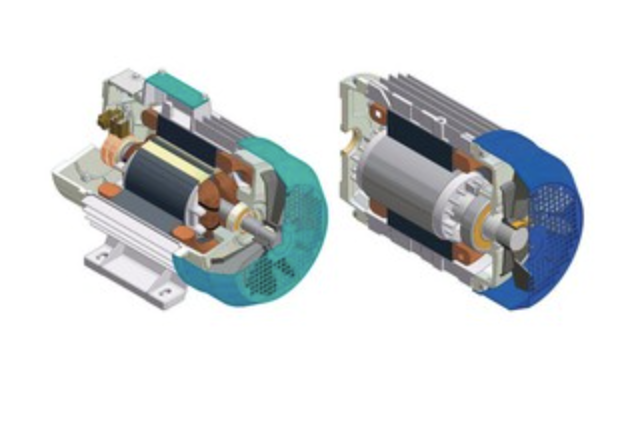

Asynchronous Motor

- This type of engine is characterised by a simplified and robust design, which helps to reduce the risk of breakdowns and makes maintenance easier.

- The rotor in these motors is usually in the form of a short-circuited cage, known as a “squirrel wheel,” which eliminates the need for a

about external electrical connections.

- The presence of fixed contacts, such as brushes, in the rotor increases its service life and reduces the need for regular maintenance.

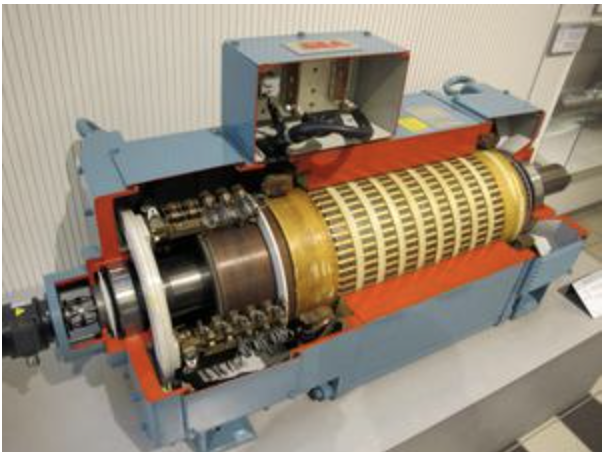

Synchronous Motor

- This type of motor is characterised by a more complex design due to the presence of windings on the rotor, which require connection to an external DC source via brushes and slip rings.

- The complexity of the design provides increased accuracy and efficiency, but also increases manufacturing and maintenance costs.

- Some models implement an excitation function to adjust the magnetic field, which improves motor performance.

Principles of Work

Asynchronous motors

- They operate on the sliding principle: the rotor rotates slightly slower than the magnetic field of the stator.

- Sliding initiates the process of generating electric current in the rotor, which leads to the creation of torque.

Synchronous motors

- The rotor rotates in strict synchronisation with the rotating magnetic field of the stator.

- Synchronisation is achieved by applying electric current to the rotor windings.

Generator applications

Asynchronous generators

- Ideal for applications with variable loads and speeds, such as wind turbines and small hydroelectric power plants.

- Their simplicity and low cost make them cost-effective for small to medium-sized projects.

- Require less maintenance and are resistant to overloading.

Synchronous generators

- Preferred in large power plants where stable and precise power generation is required.

- Allow precise control of output voltage and frequency, which is critical for connection to electrical grids.

- Their ability to excite and regulate reactive power makes them indispensable in large power grids to maintain power stability and quality.

Regulation and management

Asynchronous motors

- Variation of speed and torque is achieved by varying the voltage and frequency of the supply current.

- The use of frequency converters can improve controllability and efficiency.

Synchronous motors

- Allow for more precise speed and torque control through field current control.

- The ability to accurately control speed makes them ideal for applications where synchronised operation with the network or other machines is required.

Operational efficiency and specific features of asynchronous and synchronous motors

Asynchronous motors

Performance at different load levels:

- When induction motors do not operate at full capacity, their efficiency is reduced. This is due to the reduction in efficiency and power factor at lower loads.

- To improve performance under a variety of loads, frequency converters can be used to allow more precise adjustment of rotation speed and torque.

High inrush current:

- Induction motors are characterised by a high level of inrush current, which can exceed the rated current by a factor of 5-7. This can lead to voltage fluctuations and requires measures to protect the mains supply.

- To reduce the effect of high inrush currents, special inrush units or frequency converters are used.

Synchronous motors

Power Control:

- Synchronous motors stand out for their ability to control power precisely by regulating the field current. This allows the required power and power factor to be maintained at different load levels.

- Their high accuracy makes them ideal for use in large generator sets where stable and accurate power generation is required.

Preventing the flicker effect:

- Synchronous motors can prevent the flicker effect in power grids, which manifests itself as flickering light due to rapid voltage changes.

- Due to their ability to maintain voltage and frequency stability, they minimise voltage fluctuations caused by changes in the load, thereby reducing the risk of flicker effects.

General comparison

- Induction motors are often chosen for situations where ease of use, availability and ease of maintenance are prioritised, despite their limited efficiency at partial loads and high inrush current.

- In the context of synchronous motors, they are the preferred choice for applications where high accuracy and efficient power control are required, especially in environments where avoiding fluctuations in power quality is important..

The choice between an induction and synchronous motor in the context of generators depends on many factors, including the scale of the application, cost, required efficiency and operating conditions. The unique characteristics and advantages of both types of motors should be considered in each case.

Go to the reBITme website and find out how you can get favourable cashback and compare induction and synchronous motors to make the choice that best suits your needs and budget. Enjoy gaming to the fullest and save with reBITme!